At Minimum Squared, our core team is small and close. We are Sanela and Adrian, husband and wife.

This year our family, and business, became three, though we’ll have to wait a while until our third member can lend a hand.

This is what our day looks like, running the Spanish leather goods brand we’re so proud to call our life and our work.

Spanish Leather, Finest Coffee

Before getting down to the important business of leather goods we love a strong coffee. It has to be great quality and homemade because fresh beans and that delicious aroma get us through the day’s emails! We answer customers and work with our suppliers while we sip.

Once we’re fully awake we start to work on orders, packing, labelling and making sure everything is perfect to send out. Sometimes that’s the whole morning gone, depending on the time of year.

Working Together on Handmade Wallets

Once orders are packed and ready to go we turn to making. It’s always great to work on special colour combinations from custom orders or we’ll top up stock to make sure we can fulfill new orders quickly.

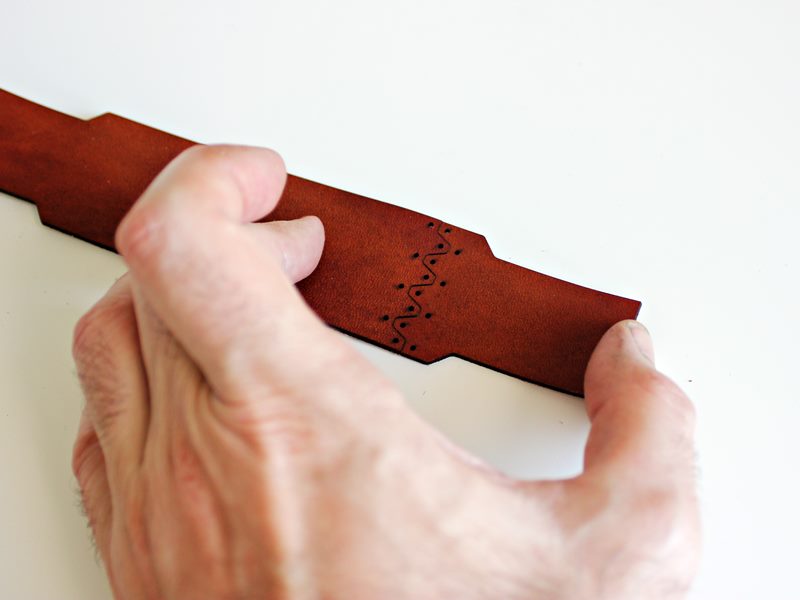

Adrian likes to choose the best leathers to hand-cut or take to the workshop to be thinned for folding. Some days mean a trip to one of our leather partners where patterns will be laser cut to the precise dimensions we need.

Sometimes Adrian might spend the whole morning or evening folding patterns or stamping the logo while I hand stitch wallets.

Inspiration and Ideas

During the day, as ideas come, we’ll write them down and maybe do a few quick sketches. We’ll often walk away, leaving an idea to rest, but if we feel like we want to return to it, we’ll do a bit more work on the specifics. We might hand-cut some patterns so we can see how the thickness of the leather will affect the folding, then we’ll probably walk away again and leave the idea to grow some more.

To build on an idea we like we’ll CAD another pattern on the computer and start paying attention to every little detail. We’ll ask ourselves questions about what each thickness, dimension and measurement should be and once we feel like we’ve got it right we’ll send the design to be made into a prototype.

Once we see the physical prototype we might sample again and we keep on going in this way until we’re totally satisfied. It’s more like a collaboration with the guy that cuts our prototypes and he understands that we like to take our time rather than rushing to follow fast fashions.

Our Approach to Slow Design

We’re all about function, design and durability for everyday items and the way we work and make is just a reflection of that. We feel like it’s better to take things slowly and make a timeless design that won’t age rather than something to be thrown away.

We surround ourselves with items like this every day and we know it’s something our customers really appreciate too. We don't cut corners and we strive to keep things at the high standard we’d want to see when we buy anything new.

The final step of our product is the packaging and it’s important that it’s not only stylish and functional, but as sustainable as possible. That’s why we go for Kraft paper rather than coloured or plastic packaging. We use boxes without glue and try to avoid adhesive as much as we can.

Taking Time Out

Later on in the day we might plan our production schedule, social media posts or talk about any changes we’d like to make to our website.

Since having a baby we’ve had to get used to a bit more flexibility in our working day. We love to go out and meet up with other artisans to share experiences and knowledge. We’ll come home for a quiet supper to relax, ready to do it all over again.

Go behind the scenes of the leathers we use for our wallets here.

Leave a comment